Article

10.12.2025

Precast Concrete commonly used by Real Estate Developers

In general, property developers, real estate developers, and construction contractors often face various challenges during project execution, such as:

-

Extended construction periods, which delay returns on investment, increase loan interest costs, and, for some projects, add expenses such as sales gallery rental fees.

-

Delayed building utilization or project handover, due to uncertainties in site activities—such as rain—or restrictions on working overtime (for example, projects surrounded by residents who need rest during evenings or weekends).

-

Nuisances to neighboring communities during construction, such as waste, dust, noise, vibration, and odors from materials. Even with preventive measures, these impacts often escape the site boundary, resulting in frequent complaints. In some projects, this even leads to construction slowdowns or temporary shutdowns, and is also environmentally unfriendly.

-

Congested construction sites, filled with materials, equipment, tools, and machinery that obstruct workflows. This also generates dust, waste, and noise pollution, affecting safety and worker health.

-

Material wastage, which is often difficult to control and results in higher construction costs than necessary.

-

Labor shortages, which increase labor expenses.

-

Inconsistent quality, as workmanship varies significantly among workers.

These recurring challenges have led many stakeholders to adopt construction technologies that help mitigate or resolve such issues. One widely recognized solution is Prefabricated Construction Technology, which addresses the three root causes of most problems:

-

Reduced labor demands, replacing manpower with machinery and tools. Many of the issues mentioned above stem from human-related variability in some form.

-

Shorter construction periods, because activities that previously had to be carried out sequentially can now be performed in parallel.

-

Reduced on-site activities, shifting many tasks to controlled factory environments. With fewer on-site operations, site congestion and pollution decrease accordingly.

This technology is based on the principle of separating building components—such as columns and beams—for off-site factory production as precast elements, while on-site work such as excavation and piling continues in parallel. Once components are produced, they are transported to the site and installed by connecting each piece together.

Precast components can be made from various materials—such as steel, concrete, or timber, individually or in combination—each with different production and installation processes. This leads to various named construction systems. The most widely known today is the Precast Concrete construction system, where components are cast in concrete—commonly referred to simply as the “precast system.”

Concrete is popular due to several advantages: high durability, wide availability, and reduced issues with internal steel corrosion when proper concrete cover is provided. Thus, Precast Concrete has become a preferred method for many types of projects. MKL therefore presents this system from the perspective that project managers should understand, structured according to the principles discussed earlier:

Segmentation of Construction Components

The segmentation of building components for Precast systems must consider overall feasibility in terms of structural engineering, manufacturing, transportation, installation, and actual usage. The key points to be aware of are as follows:

-

Because components that are separated for factory production must be reconnected during installation, connection joints are inevitable. These joints often become sources of defects if the design or quality control is inadequate—for example, water leakage or insufficient structural strength.

-

Wall panels should not be designed to be too large with too little thickness, as this may lead to cracking during demolding, cracking during transportation, and cracking during installation.

(Note: One technique commonly used to reduce cracking during demolding is to tilt the mold to reduce applied forces before pulling and lifting the component out.) -

Components should not be segmented into excessive numbers of pieces, as this will create a large number of joints. If it cannot be avoided, the joints must be carefully designed, as these are often the sources of defects during service life, as mentioned above.

However, to give readers a clearer picture, MKL would like to provide examples of how different structures—underground, on-ground, and above-ground—are segmented:

-

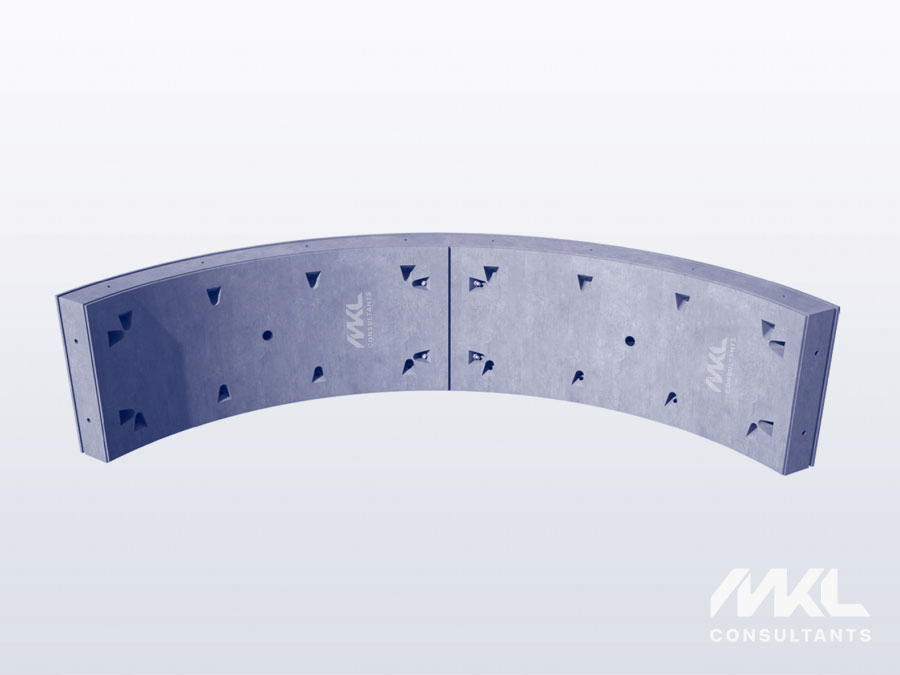

Underground MRT Tunnel Components:

The tunnel is divided into rings, called Rings, and each Ring is further segmented into 6–7 smaller Segments.

Tunnel Segments

- Box-Girder Bridge Components:

Commonly seen in Thailand projects such as the Bang Pa-In – Nakhon Ratchasima Motorway, high-speed railways, and expressways. The bridge is divided transversely into approximately 12–14 sections per span and produced using the Short Line Method.

Box Girder Segments

-

Residential Building Components:

Today, two main systems are widely used: the Load Bearing Wall System and the Skeleton Frame System.-

-

-

-

-

Load Bearing Wall System:

Precast concrete panels are designed to function as walls, columns, and beams altogether. Therefore, this system does not use traditional masonry walls, and columns or beams are typically not visible. With no space taken up by columns or beams, room volume increases and furniture layout becomes easier.

-

-

-

-

-

Load Bearing Wall

-

-

-

-

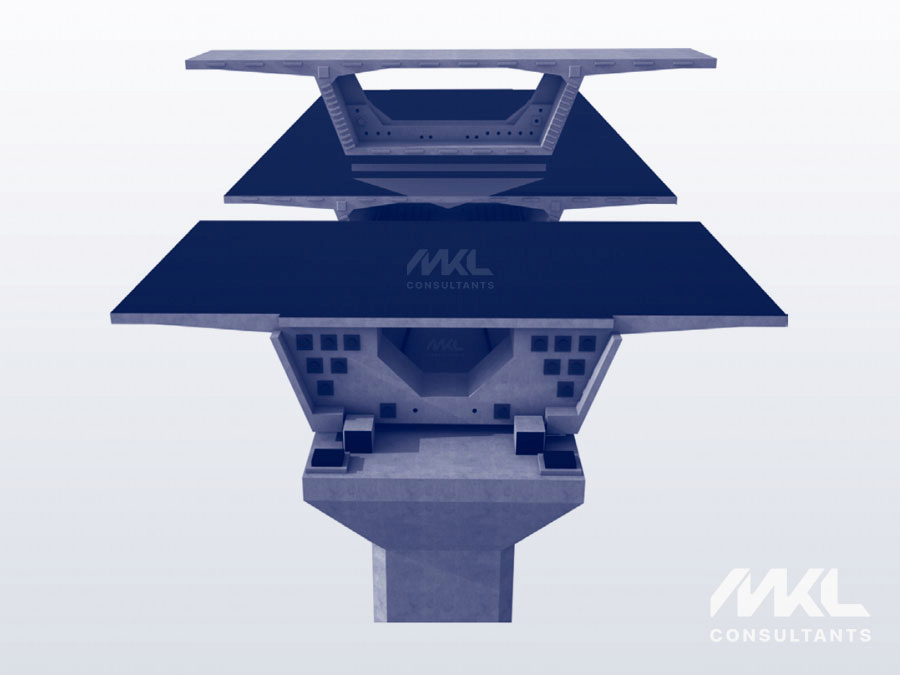

- Skeleton Frame System:

Columns and beams are precast in the factory and installed after foundations and pile caps are completed on-site. Therefore, columns and beams remain visible in this system.

- Skeleton Frame System:

-

-

-

Skeleton Frame

Factory Production

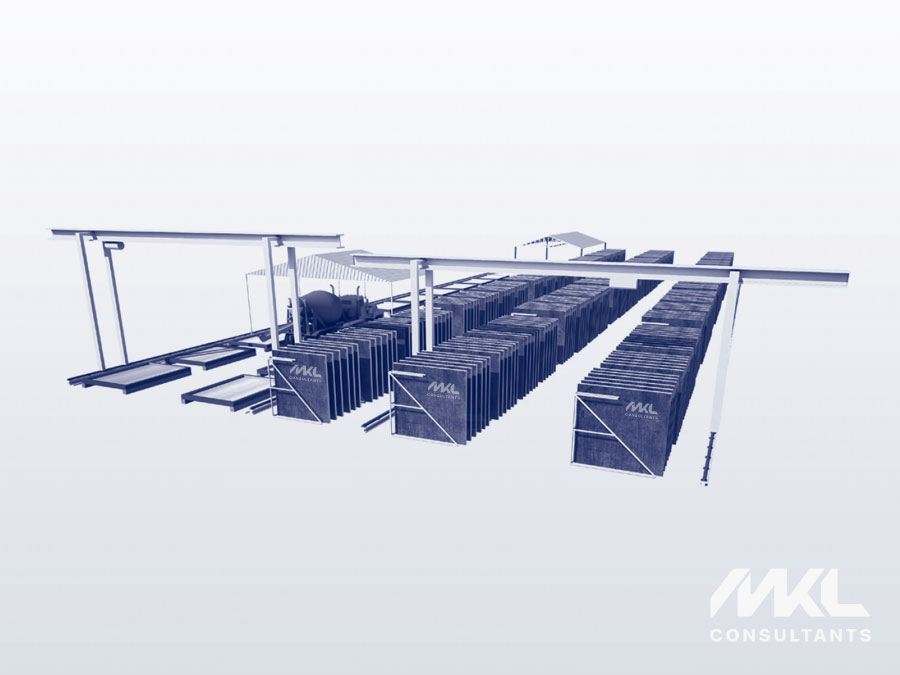

Currently, precast concrete production facilities can be categorized into two main types: manual and automatic systems. The manual system can further be divided into on-site production, in the form of a mobile yard, and off-site production, in the form of an industrial casting yard or factory. For simplicity, these will be collectively referred to as “factories.”

Note:

One of the purposes of on-site production is to reduce transportation-related costs and issues, such as delivery expenses, damage during transport, or time restrictions imposed by road regulations. However, attention must be given to construction-related vibration at the project site—such as vibrations from pile driving—which may affect the strength development of freshly cast concrete components.

Examples of Manual Precast Concrete Production

The manual system generally involves fewer complex machines and relies heavily on personnel to control operations. It is commonly used by operators who are newly adopting precast systems due to lower investment costs compared to automatic systems. Regardless of the system or production format, the primary objective remains the same: the factory must maximize production output. The greater the output, the lower the average construction cost becomes. Therefore, precast systems become more cost-effective than conventional systems only when the production volume is sufficiently large, in line with financial break-even principles.

However, for certain types of buildings—such as factories intended for product manufacturing—using precast or other prefabricated systems can significantly reduce construction time. This enables earlier commencement of production activities. When comparing the additional construction costs with the earlier generated revenue, adopting precast systems may prove financially worthwhile.

Key considerations include:

-

Factory design must, at minimum, be based on three essential pieces of information:

(1) What components are produced (design drawings and specifications),

(2) How many components are produced (production capacity), and

(3) The production flowchart or workflow.

Lack of understanding in these fundamentals may lead to operational problems, such as inefficient layout that causes workflow congestion, production delays, or even safety risks. -

The factory’s production schedule must align with the installation schedule at the construction site. Failure to do so can result in stockpile overflow due to insufficient space for newly produced components.

-

The number of moulds should not be defined only to match daily production quantities; additional moulds must be reserved for rotation when repairs are required. Otherwise, their lifespan will be significantly reduced. Because moulds represent a major cost component, proper maintenance is essential to maximize service life.

-

Residual cement sticking to moulds from previous production cycles is a major cause of mould deterioration. If not removed before the next casting, demoulding becomes difficult and may require forceful tools, resulting in mould damage. This leads to progressively worse demoulding conditions, further damage to products and moulds, and potential production loss.

-

If components from a particular mould repeatedly show damage at the same location, such as chipped corners, it is highly likely that the mould is defective and requires inspection or maintenance.

-

The factory must have a maintenance team responsible for keeping equipment and machinery in proper working condition; otherwise, equipment life will shorten and production output will drop—contradicting the goal of maximizing production.

Tools and machinery should be regularly maintained.

-

Consumable materials, such as form oil, sealants, and surface retarders, must be properly controlled. Overuse leads to unnecessary costs and potential defects. For example, excessive use of oil-based form oil can cause excessive surface air voids, which are restricted by many precast product specifications.

-

Dimensional checks during mould assembly must not be overlooked. Significant deviations from design dimensions are difficult to correct—especially in large precast components typically cast with high-strength concrete. Oversized components also increase weight, reducing structural safety factors and causing unnecessary material waste.

-

Large moulds, such as those used for bridge segments, may require external vibrators to be attached at various points and operated periodically during casting. This is because internal vibrators cannot reach certain areas. Without external vibration, cavities or honeycombs may form, leading to costly and time-consuming repairs.

-

New workers should not be immediately assigned to critical tasks that affect product quality. Frequent defects are often observed when a team undergoes personnel changes, resulting in increased repair costs.

-

Embedded items must be firmly fixed. Otherwise, they may shift during casting. Once the concrete hardens, its high strength makes cutting or drilling extremely difficult compared to masonry walls.

-

The factory should maintain production records and statistics, such as the number of defective units per production cycle and material consumption rates. This information aids in quality monitoring, cost control, training program development, and continuous improvement of production processes.

-

Project owners should station a representative at the factory, such as a construction consultant, to monitor product quality. Reinforcement and embedded items inside precast components—such as electrical conduits—cannot be inspected once the components are installed on site. Even if defects are found later, concrete removal for correction may compromise structural integrity.

Parallel Operations

As previously mentioned, the Precast Concrete system involves separating construction or building components for off-site production, while allowing other on-site activities—such as excavation and pile driving—to proceed simultaneously.

In conventional cast-in-place construction, many major tasks must be performed sequentially; for example, if the beams on the first floor have not been cast, the second-floor beams cannot be cast either.

In contrast, with the Precast system, beams for various floors can be cast at the factory at the same time, then stored at the stock yard awaiting transportation for installation. During this waiting period, repair or touch-up teams can also work on the components in advance. This parallel workflow significantly shortens overall construction time.

Installation

Each precast component, once completed, is transported and assembled on-site according to design specifications. Components are connected using different materials, devices, and methods depending on the project. To maintain continuity, MKL presents examples of installation principles using precast components from the structures previously mentioned:

-

Underground MRT Tunnel Segments:

Installation uses an Erector machine. Components are joined within the same ring and between adjacent rings using curve bolts or straight bolts, inserted into bolt holes through pre-installed sockets, depending on the designer’s choice.

Connecting tunnel segments using curve bolts.

-

Precast Segmental Box Girder Bridges:

Commonly found in Thailand, these use an Erection Truss, in either the overhead or underslung configuration. Components are connected with a post-tensioning system. -

Residential Buildings:

Mobile cranes—and in some cases shuttle lifts—are commonly used.

Installation of Precast Components for Residential Buildings.

Jointing systems fall into two main categories: Dry Joint Systems such as bolting and welding, and Wet Joint Systems such as dowels combined with non-shrink grout.

Designers today continually refine joint systems to improve installation speed, structural performance, and long-term reliability.

Summary

Given that the key objectives of construction work consist of scope, quality, time, and cost, comparing the conventional cast-in-place method with the Precast Concrete system (under an identical scope) shows that:

-

Time is faster because many activities can occur in parallel.

-

Cost is lower when the production volume is large enough to achieve economies of scale.

-

Quality is theoretically higher because components are produced at a factory, at ground level, where workers and inspectors can work more comfortably and consistently. Labor skills can also be standardized more easily.

However, installation quality—especially joint performance—must be closely monitored. Any system involving joints inherently carries risks such as water leakage and durability issues. The quality of connections depends on various factors: worker skills, preparation methods, joint design, and materials/equipment used.

Additional Considerations

It is important to understand that every system has both strengths and weaknesses. When adopting the Precast Concrete system, one should study not only the advantages but also the limitations to plan appropriate mitigation. For example, in a bearing-wall precast system, walls serve as part of the structural system, meaning they cannot be demolished like conventional masonry walls.